Introduction

When it comes to surfactants used in various household and industrial cleaning products, alkyl ether sulfates hold a significant position. These compounds are widely employed in detergents, shampoos, and other personal care products due to their excellent foaming and cleansing properties. If you’re considering entering the chemical manufacturing industry, setting up an alkyl ether sulfates manufacturing plant could be a strategic and profitable investment. This article aims to provide a comprehensive Alkyl Ether Sulfates Manufacturing Plant Project Report for establishing an alkyl ether sulfates manufacturing plant, offering insights into the production process, raw material sourcing, operational aspects, and more.

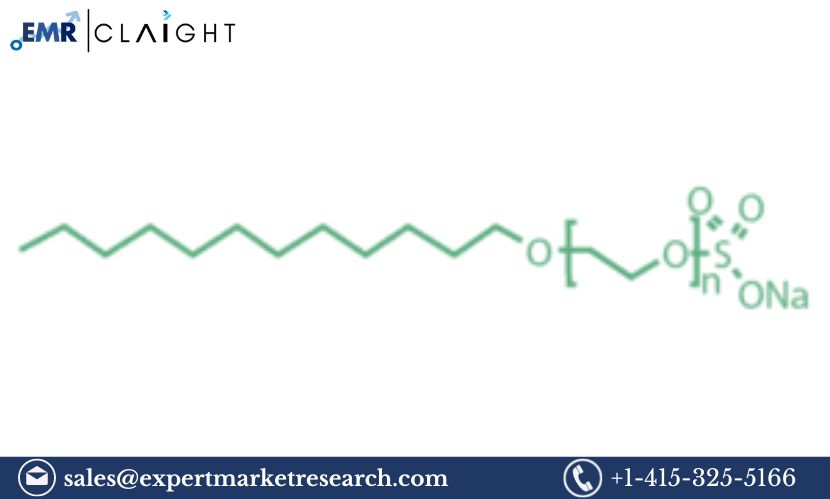

What Are Alkyl Ether Sulfates?

Alkyl ether sulfates are surfactants derived from fatty alcohols and ethoxylation processes. They are commonly used in a range of products that require foaming and cleansing agents. Their ability to reduce surface tension makes them an ideal choice in detergents, shampoos, and cosmetics. Alkyl ether sulfates are favored because they offer excellent solubility in water and are less irritating to the skin compared to other surfactants.

Get a Free Sample Report with Table of Contents @

Overview of the Manufacturing Process

The manufacturing of alkyl ether sulfates involves several steps, starting from raw material preparation to the final packaging of the product. Understanding the general process flow can help prospective manufacturers plan their operations efficiently.

- Raw Material Preparation

The primary raw materials required include fatty alcohols and sulfur trioxide. These are the building blocks for producing alkyl ether sulfates, and sourcing them from reliable suppliers is critical for ensuring product quality. - Ethoxylation

The first major step in production is the ethoxylation of fatty alcohols. In this process, fatty alcohols are reacted with ethylene oxide to produce alcohol ethoxylates. The reaction must be carefully controlled to achieve the desired degree of ethoxylation, which influences the final product’s properties. - Sulfation

The next step involves sulfation, where the alcohol ethoxylates are reacted with sulfur trioxide. This process results in the formation of alkyl ether sulfates. The choice of equipment and reaction conditions are critical at this stage, as they determine the final product’s quality, yield, and performance characteristics. - Neutralization and Purification

Once sulfation is complete, the product is neutralized using a base such as sodium hydroxide. This step helps stabilize the surfactant. The neutralized product is then purified to remove any unreacted materials and impurities, ensuring that the final product meets industry standards. - Packaging and Storage

After purification, the alkyl ether sulfates are ready for packaging. They are typically stored in large containers and sold in liquid form to industries manufacturing detergents and personal care products. Proper storage conditions are essential to maintain the quality and shelf life of the product.

Plant Setup and Key Considerations

When planning to set up an alkyl ether sulfates manufacturing plant, there are several factors to consider:

- Location: The plant should be situated in an industrial area with easy access to raw material suppliers and distribution networks. Proximity to transport hubs can help reduce logistics costs.

- Equipment: The key equipment required includes ethoxylation reactors, sulfation units, neutralization tanks, and purification systems. Choosing the right equipment is essential to ensure smooth operations.

- Regulatory Compliance: Alkyl ether sulfate manufacturing involves the handling of chemicals, so adhering to environmental and safety regulations is crucial. Make sure to obtain the necessary permits and follow guidelines to minimize environmental impact and ensure worker safety.

Raw Material Sourcing and Supply Chain Management

For a successful alkyl ether sulfates manufacturing plant, maintaining a consistent supply of high-quality raw materials is vital. Establishing relationships with reliable suppliers of fatty alcohols and sulfur trioxide can ensure smooth operations and minimize production delays. Additionally, having contingency plans for sourcing alternative suppliers can mitigate the risk of supply chain disruptions.

Quality Control and Testing

Quality control is a critical aspect of alkyl ether sulfate production. Regular testing of raw materials and final products ensures that the surfactants meet industry standards. Testing for parameters such as pH, concentration, and purity is essential to ensure the product’s efficacy in various applications.

Market Outlook and Industry Trends

The demand for alkyl ether sulfates is driven by the growing personal care and household cleaning products industries. With increasing consumer awareness regarding hygiene and cleanliness, the market for surfactants like alkyl ether sulfates is expected to expand. In addition, the trend toward environmentally friendly and biodegradable surfactants is pushing manufacturers to innovate and improve their products.

Production Costs and Financial Planning

Establishing a manufacturing plant requires a clear understanding of the associated costs. Key cost components include raw material procurement, equipment purchase, labor, utilities, and regulatory compliance. While it’s important to minimize costs, compromising on quality or safety standards can lead to operational risks and reputational damage. Proper financial planning and budgeting are crucial for long-term success.

Sustainability in Alkyl Ether Sulfates Manufacturing

Sustainability is becoming an essential consideration in the chemical manufacturing industry. By adopting green manufacturing practices, such as using renewable energy sources or recycling water and waste, manufacturers can reduce their environmental footprint. Additionally, producing biodegradable alkyl ether sulfates can give manufacturers a competitive edge in markets that prioritize eco-friendly products.

FAQ

1. What are the primary applications of alkyl ether sulfates?

Alkyl ether sulfates are primarily used in personal care products like shampoos and body washes due to their excellent foaming and cleansing properties. They are also used in household cleaning products such as laundry detergents and dishwashing liquids.

2. What factors should be considered when selecting equipment for the manufacturing plant?

Key factors include the capacity of the equipment, energy efficiency, ease of maintenance, and compliance with safety standards. It’s also important to choose equipment that can handle the specific chemical reactions involved in producing alkyl ether sulfates.

3. How can manufacturers ensure product quality in alkyl ether sulfate production?

Implementing stringent quality control measures, including testing raw materials and finished products for parameters like pH and concentration, is essential. Regular equipment maintenance and adhering to manufacturing best practices can also help maintain consistent product quality.

4. What are the environmental concerns associated with alkyl ether sulfate production?

The production of alkyl ether sulfates involves the use of chemicals that may have environmental impacts if not handled properly. Manufacturers must comply with environmental regulations, manage waste responsibly, and explore sustainable practices to reduce their environmental footprint.

5. How does the market outlook for alkyl ether sulfates look?

The market for alkyl ether sulfates is growing, driven by the demand for personal care and household cleaning products. The shift toward environmentally friendly products is also pushing the development of biodegradable surfactants, which presents opportunities for manufacturers.

6. Can alkyl ether sulfates be produced in an eco-friendly manner?

Yes, manufacturers can adopt sustainable practices such as using renewable energy, recycling water, and reducing waste to produce alkyl ether sulfates in an eco-friendly manner. Additionally, producing biodegradable variants of these surfactants can appeal to environmentally conscious consumers.

7. What are the main challenges in alkyl ether sulfate manufacturing?

Challenges include maintaining consistent product quality, managing the supply chain for raw materials, complying with environmental and safety regulations, and controlling production costs. Overcoming these challenges requires efficient planning, reliable sourcing, and adherence to industry standards.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au