Proper maintenance of Shale Shaker Screens is essential for ensuring the longevity of the equipment and enhancing its performance. In industries like oil and gas, where efficiency and safety are critical, maintaining these screens can prevent costly downtime and improve the separation process. Whether you’re working in drilling operations or other sectors that require shale shakers, knowing how to care for the screens is vital. Below are key maintenance tips to extend the lifespan of your Shale Shaker Screen and optimize its performance.

1. Regular Inspection and Cleaning

To keep your Shale Shaker Screen functioning at its best, it’s important to conduct regular inspections. Look for wear and tear, torn mesh, or loose fastenings that could compromise the screen’s effectiveness. Cleaning the screens regularly is also crucial, as accumulated debris can obstruct the mesh and reduce separation efficiency. Using specialized cleaning tools, remove mud, cuttings, and other materials that can get stuck on the screen.

In industrial settings where safety is paramount, it’s essential to use the right cleaning methods. Working with Safety Equipment Suppliers in Dubai ensures that workers have access to protective gear, such as gloves and eye protection, to minimize risks during cleaning.

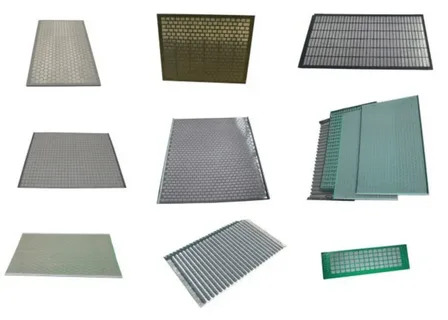

2. Choose the Right Screen for Your Operations

Selecting the appropriate Shale Shaker Screen for your specific drilling needs is key to maximizing efficiency. There are different screen types based on mesh size and construction. For example, finer screens may offer better separation but require more frequent cleaning. Understanding the requirements of your operation and consulting with experts can help you choose the right screen. Heavy Duty API Thread Protectors are also useful in maintaining equipment by safeguarding threads during drilling operations.

3. Proper Handling and Storage

Improper handling of Shale Shaker Screens can lead to damage and reduce their operational lifespan. When removing or installing screens, handle them with care to avoid bending or tearing the mesh. Additionally, storing screens in a dry, clean area away from direct sunlight helps prevent damage caused by environmental factors. For facilities operating in harsh environments, using Anti Slip Mats from Suppliers in Dubai can ensure a safe workspace, reducing the risk of accidents when handling heavy equipment.

4. Monitor Pressure and Tension

Ensuring proper tension on your Shale Shaker Screen is critical for its performance. Over-tensioning can cause the screen to tear, while under-tensioning can lead to improper separation and reduced efficiency. Regularly check the screen’s tension and make necessary adjustments.

Monitoring pressure during operation is equally important. If the system pressure is too high, it can lead to premature wear and tear on the screens. Utilizing tools from Pressure Gauges Suppliers in UAE can help you accurately monitor system pressure and ensure it stays within optimal limits for longer screen life.

5. Replace Worn or Damaged Screens Immediately

Ignoring a damaged screen can compromise the entire operation. Torn or worn-out screens should be replaced immediately to avoid downtime and potential contamination of the drilling fluid. CTP and CAT Parts Suppliers in UAE offer high-quality replacement parts that ensure smooth operations when dealing with damaged components.

6. Maintain Environmental and Worker Safety

In the oil and gas industry, maintaining safety protocols is vital. Not only should the screens be well-maintained, but the environment in which they operate should also be safe. Implementing Safety Nets in Dubai UAE around the equipment can protect workers from potential hazards during operations. Additionally, Bug Blowers Suppliers in Dubai provide essential tools to keep your workspace free from pests that could interfere with the equipment.

7. Use Proper Bolting and Hydraulic Tools

When installing or removing Shale Shaker Screens, ensure that you use the correct tools for the job. Bolting tools, Hydraulic Tools, and Hydraulic Jacks Suppliers in UAE offer the right equipment to make the process easier and safer, preventing damage to the screens or surrounding machinery during installation.

8. Optimize Screen Performance with the Right Mats

In environments like oil and gas, where the floor can become slick with fluids and debris, Rubber Mats for the Oil and Gas Industry in Dubai are an excellent way to maintain stability around the shale shaker. These mats can reduce the risk of accidents and provide a sturdy foundation for equipment and workers, enhancing both safety and efficiency.

Conclusion

Proper maintenance of Shale Shaker Screens is essential to prolonging their lifespan and optimizing their performance. From regular inspections and cleaning to using the right handling techniques and monitoring pressure levels, these steps can ensure that your shale shaker system runs smoothly and efficiently. For industrial applications, working with trusted suppliers of Safety Equipment, Pressure Gauges, and Heavy-Duty API Thread Protectors is key to maintaining a safe and productive environment.