Introduction

In today’s rapidly advancing industrial landscape, precision, efficiency, and customization are crucial for success. Laser marking and etching technologies have become essential for industries as diverse as electronics, automotive, jewelry, and medical devices. These technologies, combined with innovative tools such as laser markers, advanced laser etching software, and the trusted EzCad software, provide businesses with unmatched accuracy and productivity. By adopting these solutions, companies can enhance their marking and engraving processes to meet ever-evolving market demands.

What is Laser Marking?

Laser marking is a process that uses focused laser beams to leave permanent marks on a material’s surface. These marks can include text, serial numbers, barcodes, logos, or intricate patterns. Materials commonly used in laser marking include metals, plastics, ceramics, and glass. The process ensures precision, durability, and tamper-proof results, making it invaluable for industries requiring clear, detailed, and long-lasting markings.

Compared to traditional methods, laser marking offers significant advantages, such as non-contact operation, reduced waste, and compatibility with automation systems. As such, it’s a preferred method for high-volume production and applications demanding exacting standards.

The Role of Laser Etching Software

The performance of a laser marker is highly dependent on the software that drives it. Laser etching software provides the interface and tools necessary to design, control, and execute laser marking tasks with precision. High-quality software ensures seamless operation and maximizes the capabilities of the laser hardware.

Key features of advanced laser etching software include:

- Versatile Design Tools: Support for vector graphics, 2D and 3D designs, and a wide range of fonts. Users can easily import files or create intricate designs from scratch.

- User-Friendly Interface: Simplifies operation for both beginners and experienced users, reducing the learning curve.

- Precision Control: Offers detailed adjustments for laser power, speed, frequency, and focus, ensuring optimal results across different materials and applications.

- Automation Capabilities: Integrates with production lines for automated and consistent batch marking, improving efficiency.

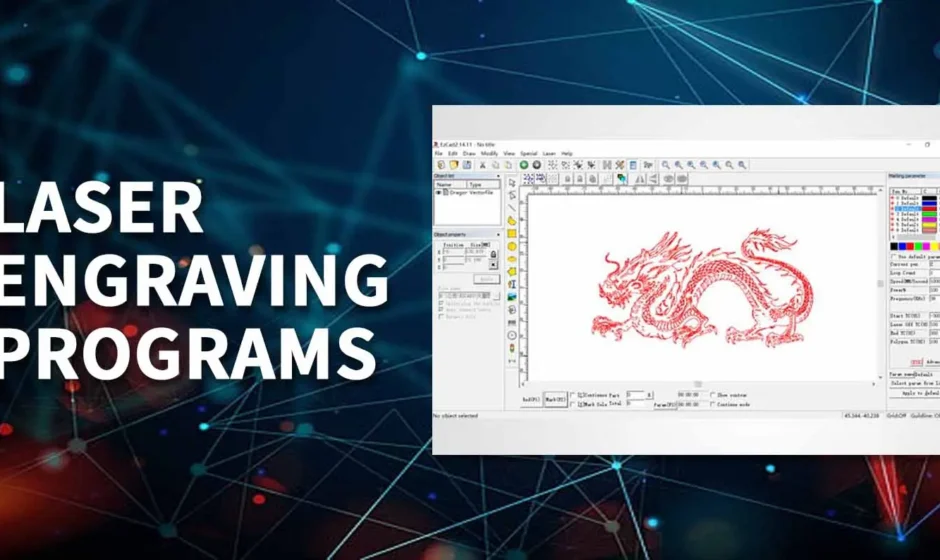

EzCad Software: The Industry Leader

EzCad software stands out as a premier choice for laser marking and etching. Renowned for its reliability and functionality, it’s compatible with a wide range of laser machines, including fiber lasers, CO2 lasers, and UV lasers. EzCad’s robust features cater to various industries and applications, making it a preferred solution for businesses of all sizes.

Some of the standout features of EzCad include:

- Broad Material Compatibility: EzCad supports marking on metals, plastics, ceramics, and more, enabling versatility for diverse projects.

- High Compatibility: It works seamlessly with widely used laser control boards, such as BJJCZ, ensuring smooth and reliable operation.

- Advanced Tools: Features like 3D engraving, rotary marking, and multi-layer etching make it suitable for complex and high-precision tasks.

- Customizable Parameters: Users can fine-tune laser settings to achieve the desired depth, speed, and quality.

- Regular Updates: Continuous software enhancements keep EzCad at the forefront of laser marking technology.

Applications of Laser Marking and Etching

Laser marking and etching technologies, powered by EzCad software, are widely used across industries for various applications:

- Electronics: Marking serial numbers, QR codes, and component labels on circuit boards.

- Jewelry: Engraving intricate patterns, custom designs, and personalized messages on metal surfaces.

- Automotive: Adding part numbers, VIN codes, and tamper-proof identification marks.

- Medical Devices: Ensuring compliance by marking tools and equipment with regulatory codes.

- Promotional Products: Branding metal or plastic items with company logos and text.

- Aerospace: Precision marking on sensitive components used in high-stakes environments.

Why Choose Laser Marking Technology?

Investing in laser marking technology and reliable laser etching software is a strategic move for businesses aiming to boost production quality and efficiency. Here are some key benefits:

- Exceptional Precision: Laser markers offer unparalleled accuracy, allowing for intricate and repeatable designs with minimal material waste.

- Cost-Effective: The non-contact nature of laser marking reduces wear and tear, lowering maintenance costs and eliminating the need for consumables like inks or stencils.

- Eco-Friendly: Laser marking is a clean and environmentally friendly process, producing no hazardous byproducts.

- Durable Results: Marks created by lasers are highly resistant to fading, scratching, or environmental wear, ensuring long-lasting quality.

- Scalability: From small workshops to large-scale manufacturing facilities, laser marking systems can scale to meet production needs.

Why EzCad Software is Essential for Laser Marking

EzCad software enhances the capabilities of laser markers by providing a powerful platform for design and execution. Its advanced features make it indispensable for businesses seeking to maximize the performance of their laser systems. Whether you’re creating simple logos or complex 3D engravings, EzCad delivers consistent and high-quality results.

Conclusion

In an era where precision and customization are more important than ever, laser marking and etching technologies, combined with advanced tools like EzCad software, have become indispensable for industries worldwide. By investing in these technologies, businesses can achieve superior accuracy, streamline production processes, and maintain a competitive edge in the market.

Whether you’re in electronics, automotive, medical devices, or promotional products, adopting laser marking systems and software is a game-changer. Explore the potential of laser markers, laser etching software, and EzCad today to revolutionize your production capabilities and meet the demands of a dynamic industrial world.

RobertFrava 15 Jun 2025

¡Hola, aventureros del desafío !

Mejores casinos online extranjeros con crupieres en vivo – https://casinoextranjerosespana.es/# casinos extranjeros

¡Que disfrutes de asombrosas tiradas exitosas !

RobertCAw 15 Jun 2025

¡Saludos, amantes de la adrenalina !

Casino online sin licencia EspaГ±a sin verificaciГіn – https://casinossinlicenciaenespana.es/# casinos sin licencia

¡Que vivas sesiones inolvidables !

EdwardWap 16 Jun 2025

¡Saludos, seguidores de la diversión !

Casinosextranjerosenespana.es – Juegos y diversiГіn – https://www.casinosextranjerosenespana.es/ п»їcasinos online extranjeros

¡Que vivas increíbles jugadas excepcionales !

Richardatofe 17 Jun 2025

¡Hola, buscadores de fortuna !

Casinos sin licencia espaГ±ola sin restricciones – п»їcasinossinlicenciaespana.es casinos sin licencia espaГ±ola

¡Que experimentes botes sorprendentes!

Douglasbar 17 Jun 2025

¡Hola, participantes del desafío !

Casino fuera de EspaГ±a con promociones semanales – https://www.casinoonlinefueradeespanol.xyz/ casino online fuera de espaГ±a

¡Que disfrutes de asombrosas movidas brillantes !

MichaelIdern 18 Jun 2025

¡Saludos, entusiastas de la aventura !

casino online extranjero sin lГmites de apuesta – https://www.casinosextranjero.es/# casino online extranjero

¡Que vivas increíbles recompensas sorprendentes !

CharlesVal 18 Jun 2025

¡Saludos, aficionados a los desafíos!

Tips para aprovechar bonos de casinos extranjeros – https://www.casinoextranjerosenespana.es/ casinoextranjerosenespana.es

¡Que disfrutes de oportunidades exclusivas !

HaroldPoova 19 Jun 2025

¡Hola, amantes del entretenimiento !

casinoextranjero.es – el sitio top para apostadores – https://www.casinoextranjero.es/ casinoextranjero.es

¡Que vivas victorias legendarias !

WayneMut 20 Jun 2025

¡Bienvenidos, cazadores de tesoros !

Casino fuera de EspaГ±a con menГє multijuego – https://casinoporfuera.guru/# casino por fuera

¡Que disfrutes de maravillosas tiradas afortunadas !

Jamesmeede 21 Jun 2025

¡Saludos, entusiastas del azar !

casinosonlinefueraespanol: guГa segura 2025 – п»їhttps://casinosonlinefueraespanol.xyz/ casinos fuera de espaГ±a

¡Que disfrutes de jackpots fascinantes!

Martinbagma 22 Jun 2025

¡Bienvenidos, seguidores de la victoria !

Casino online fuera de EspaГ±a con salas privadas – https://www.casinofueraespanol.xyz/ casinos online fuera de espaГ±a

¡Que vivas increíbles victorias legendarias !

Jamesomirm 22 Jun 2025

¡Hola, aventureros del riesgo !

casinosextranjerosdeespana.es – sin documentos – https://www.casinosextranjerosdeespana.es/# п»їcasinos online extranjeros

¡Que vivas increíbles jackpots sorprendentes!