When it comes to mechanical systems, springs are crucial components used in a variety of applications. Among the many types of springs, Compression Spring near Me and custom torsion springs are two of the most widely used. Whether you are designing a new product, upgrading an existing system, or improving performance, understanding the role of these springs is essential. In this article, we will explore the importance of compression springs and custom torsion springs, how they work, and why they are indispensable for many industries.

What Are Compression Springs and How Do They Work?

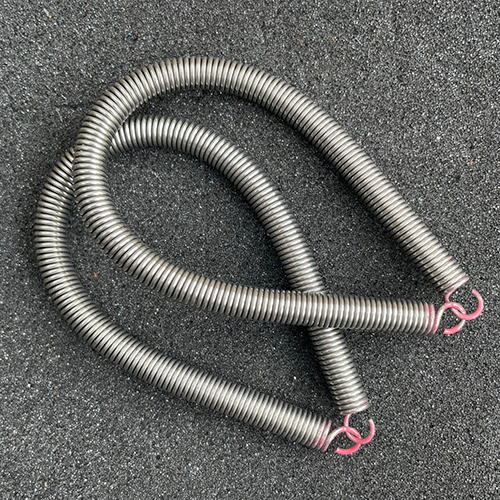

Compression springs are one of the most commonly used types of springs in mechanical systems. They are designed to resist compressive forces, meaning they are used to store potential energy when compressed. These springs work by using a coiled wire that can be compressed and expanded under force. As the force is applied, the coil compresses, storing energy, and when the force is removed, the spring returns to its original shape.

The functionality of compression springs is simple yet effective. They play a vital role in mechanisms that require energy storage and release, such as automotive suspensions, electronic devices, and mechanical switches. The applications of compression springs are vast, from providing resistance to cushioning impacts, to acting as a load-bearing component.

Why Should You Consider Custom Torsion Springs?

Custom torsion springs are another essential type of spring, primarily designed to provide rotational force or torque. These springs work by twisting, rather than compressing. When the spring is twisted, it stores energy, and when the force is released, the spring attempts to return to its original shape, providing rotational energy. This type of spring is typically used in situations where a rotating motion or force is needed.

Custom torsion springs are particularly useful in applications where standard springs do not meet the specific requirements. With custom torsion springs, the design can be tailored to meet exact load specifications, size constraints, and desired rotational forces. For example, custom torsion springs are often used in applications such as garage doors, clipboards, and even mechanical clocks.

By customizing torsion springs, manufacturers can ensure that the springs are optimized for their intended purpose. This ensures greater performance and longevity, while also improving the efficiency of the system.

How Do Compression Springs and Custom Torsion Springs Differ?

While both compression springs and custom torsion springs are used to store and release energy, their mechanisms and applications are different. Compression springs work by compressing and expanding under axial force, whereas torsion springs work by twisting and generating rotational force.

Compression springs are primarily used in linear applications, such as providing resistance to compressive forces in shock absorbers, mattress springs, and even pens. Torsion springs, on the other hand, are used for rotational purposes, such as turning a drum, rotating a door, or opening a clip.

The materials used for both types of springs can vary depending on the application. For example, both compression and torsion springs are often made from high-quality steel, stainless steel, or other durable metals that can withstand repeated cycles of stress without losing their performance.

How to Choose Between Compression Springs and Custom Torsion Springs?

Choosing the right spring for your project depends on the type of motion required. If your application involves linear motion, such as compression and decompression, a compression spring is the best choice. For example, compression springs are commonly used in car suspension systems, medical devices, and industrial machinery.

On the other hand, if your application requires rotational motion or torque, then custom torsion springs would be the better option. These are ideal for applications where the spring needs to store and release rotational energy. Some examples of torsion spring applications include spring-loaded clips, rotating mechanisms, and garage door springs.

It is important to carefully assess your specific needs before choosing between these two types of springs. Factors such as load requirements, space limitations, and material constraints should all be considered in order to select the best option for your project.

What Are the Benefits of Custom Springs?

Custom springs, whether they are compression or torsion springs, offer numerous advantages over off-the-shelf, standardized springs. Some of the key benefits of custom springs include:

- Precise Design: Custom springs can be engineered to meet the exact specifications of your project, ensuring optimal performance. This includes factors such as load capacity, size, material, and shape.

- Tailored Performance: Custom springs can be designed to handle specific forces and stresses that standard springs may not be able to manage. This makes them ideal for specialized applications.

- Cost-Effectiveness: While custom springs may seem like a more expensive option initially, they can help reduce long-term costs by improving the efficiency and lifespan of the system. For example, a custom torsion spring may increase the lifespan of a mechanical device, reducing the need for frequent replacements.

- Improved Efficiency: By ensuring that the spring is designed specifically for the application, you can avoid over-engineering or under-engineering the system, which can result in better energy efficiency.

- Durability: Custom springs are built to last longer and withstand repeated cycles of stress. With the right material selection and design, custom springs can operate in harsh environments and endure extreme conditions.

How to Order Custom Compression Springs and Torsion Springs?

Ordering custom compression springs and custom torsion springs involves several key steps:

- Determine the Specifications: First, you need to define the requirements for your spring. This includes the load, force, dimensions, material, and application. If you’re unsure about the specifications, it’s advisable to work with a spring manufacturer who can help you understand the necessary details.

- Choose the Material: The material of the spring plays a crucial role in its performance. Common materials include stainless steel, high-carbon steel, and alloy steels, each offering unique benefits based on the intended use.

- Select the Manufacturing Process: Depending on the complexity of the spring, different manufacturing processes can be employed. This may include cold coiling, hot coiling, or precision grinding to meet your design requirements.

- Provide the Design: If you have a specific design in mind, you can provide it to the manufacturer. Alternatively, the manufacturer can assist you in creating a custom design based on your specifications.

- Quality Control: Before the springs are produced in bulk, manufacturers will typically conduct tests to ensure they meet the required standards. These tests include load testing, dimensional checks, and material inspection to ensure durability and performance.

Conclusion: Why Compression Springs and Custom Torsion Springs Matter

Both compression springs and custom torsion springs are essential for various industries, playing key roles in energy storage, force resistance, and rotational torque. Compression springs are ideal for applications involving linear motion, while custom torsion springs are designed to handle rotational forces. The choice between these two types of springs depends on the specific requirements of your project.

By opting for custom-designed springs, you can ensure that your mechanical system performs optimally, offering better durability, efficiency, and longevity. Whether you need custom torsion springs for a rotating mechanism or compression springs for shock absorption, choosing the right spring will make all the difference in your project’s success.

If you’re unsure which spring is right for your application, it’s always a good idea to consult with a spring manufacturer who can guide you through the design and selection process.