Compression springs are vital components used in a wide array of industries. Their versatility, reliability, and durability make them indispensable in applications ranging from automotive to medical devices. But what exactly makes compression springs so essential, and why are they in demand across various sectors? Let’s explore the reasons behind the widespread use of compression springs and why you might search for a “compression spring near me.”

What Are Compression Springs?

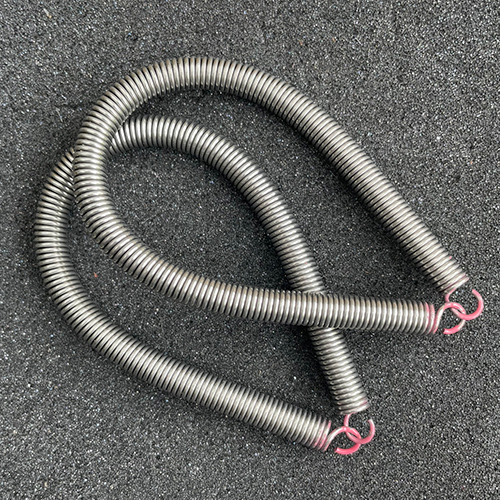

Compression springs are mechanical devices designed to resist compressive forces. They are typically made of coiled wire, which can either be open or tightly wound, depending on the required application. The primary function of a compression spring is to store energy when compressed and release that energy when the force is removed. They are widely used in applications where this energy storage and release are essential.

These springs are most commonly made of materials such as stainless steel, carbon steel, or alloy steel, depending on the specific requirements for strength, durability, and corrosion resistance.

Why Are Compression Springs So Important?

Compression springs are essential because they provide a simple and efficient way to store and release energy in mechanical systems. Their role in controlling movement, providing resistance, and absorbing shocks makes them a critical component in many industries. Here are some reasons why compression springs are used so extensively:

- Energy Storage and Release: Compression springs excel at storing energy when compressed and releasing it in a controlled manner. This energy storage function is crucial in devices such as car suspensions, mattresses, and even pens.

- Shock Absorption: Compression springs are used in applications that involve absorbing or dampening shock or vibration. This makes them essential in machinery, vehicles, and electronics, where avoiding damage from impact or movement is necessary.

- Force Regulation: Compression springs are also useful for regulating force in mechanical systems. For instance, they are used in devices where a constant force is required, such as in valves, switches, or in certain types of industrial machinery.

- Cost-Effectiveness and Durability: Compression springs are relatively simple to design and manufacture, making them cost-effective for mass production. Their ability to withstand repeated use without failure is why they’re used in a variety of long-lasting applications, even in harsh environments.

- Versatility: With their wide range of available sizes and material options, compression springs are customizable for different needs, from the smallest electronic components to large industrial machines.

How Are Compression Springs Used in Various Industries?

Compression springs are found in nearly every sector due to their adaptability. Here’s a look at how these springs are employed in different industries:

Automotive Industry

In the automotive sector, compression springs are used in various components, such as in car suspension systems, shock absorbers, and clutch systems. They play a vital role in ensuring the vehicle’s stability, smooth ride, and control. For example, the suspension system uses compression springs to absorb the impact from bumps on the road, reducing wear and tear on the vehicle while providing a more comfortable experience for the driver and passengers.

Electronics and Appliances

Compression springs are widely used in electronic devices, such as printers, cameras, and mobile phones. They help with buttons, switches, and mechanisms where energy storage and release are required. In appliances like washing machines, dishwashers, and microwave ovens, compression springs are used for door latches, hinges, and other moving parts to ensure proper operation.

Medical Devices

In the medical industry, compression springs are essential in the design of various medical devices such as infusion pumps, surgical instruments, and prosthetics. They provide the necessary force regulation for consistent operation in delicate equipment, ensuring precise functions while maintaining patient safety. For example, in prosthetic limbs, compression springs help maintain controlled movement, mimicking natural joint actions.

Aerospace Industry

Compression springs play a crucial role in the aerospace industry by being part of critical components such as landing gear, cabin pressure systems, and even in aircraft engines. These springs are designed to withstand extreme conditions, including high levels of stress, temperature variations, and vibration. They are used to absorb shock and to keep vital components operational in flight.

Industrial Machinery

In industrial applications, compression springs are used in machines that require force regulation, shock absorption, or vibration damping. They are integral in conveyor belts, hydraulic systems, and mechanical arms, where they assist in maintaining consistent force and energy levels during operation. Their ability to work in tough environments makes them a preferred choice for industries requiring durable and high-performance components.

What Are the Key Benefits of Using Compression Springs?

- Reliability and Performance: Compression springs can handle repeated compression and decompression cycles without losing their ability to function. Their design and materials allow for long-term, reliable performance, making them indispensable in mission-critical applications.

- Customizability: Depending on the specific application, compression springs can be customized in terms of size, material, and spring rate. This flexibility ensures that they can meet the demands of any industrial sector, from heavy machinery to delicate medical equipment.

- Space Efficiency: The compact design of compression springs allows them to be used in a variety of small or confined spaces. This is particularly beneficial in industries like electronics, where space is often limited but the need for reliable components remains high.

- Durability: Compression springs are designed to endure high levels of stress and fatigue, making them ideal for environments where durability is essential. Whether in high-temperature industrial applications or in everyday consumer products, these springs are built to last.

- Cost-Effective Solution: Due to their simple design and ease of manufacturing, compression springs are an affordable solution for many applications. This cost-efficiency, combined with their long lifespan, makes them a great value for industries worldwide.

Where Can You Find High-Quality Compression Springs?

When searching for high-quality compression spring near me, it’s important to choose a supplier that offers durable, reliable, and customizable springs tailored to your needs. Acxess Spring is a leading manufacturer of compression springs, known for its wide variety of high-quality products and exceptional customer service. Whether you’re in need of springs for automotive, medical, or industrial use, Acxess Spring ensures that their products meet the highest standards of quality and performance.

In conclusion, compression springs are an essential part of numerous industries due to their ability to store and release energy, absorb shocks, and regulate forces. Their versatility, reliability, and cost-effectiveness make them an indispensable component in countless applications. Whether you’re looking for a “compression spring near me” or need to source custom springs, companies like Acxess Spring offer the expertise and products needed to meet the demands of any industry.