In the rapidly evolving landscape of modern manufacturing, graphite dies have emerged as a cornerstone technology, facilitating efficiency, precision, and durability across a wide spectrum of industrial sectors. As industries push for innovation, cost-effectiveness, and sustainability, graphite dies consistently outperform traditional die materials—especially in high-temperature, high-stress environments.

What Are Graphite Dies?

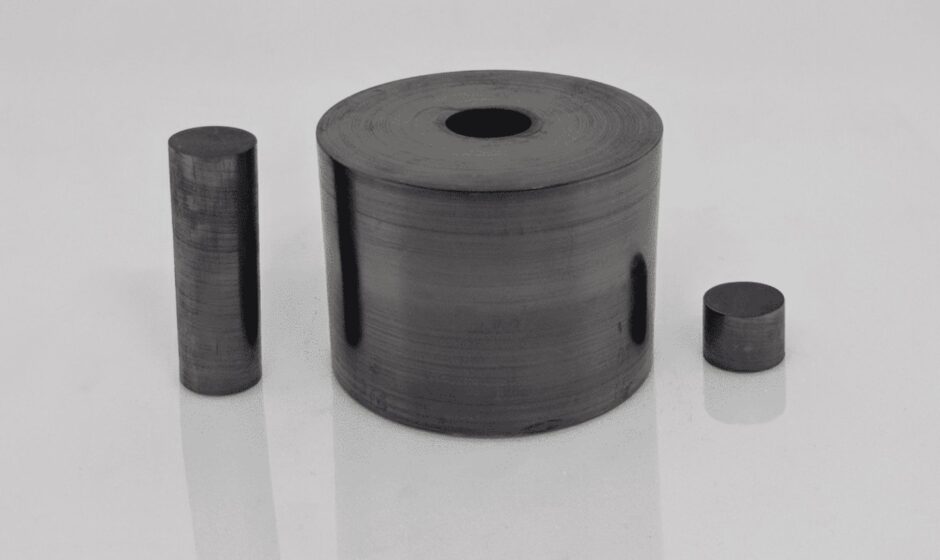

Graphite dies are specialized tooling components crafted from synthetic graphite, known for its exceptional thermal stability, electrical conductivity, chemical inertness, and machinability. A graphite die is commonly used in processes such as metal extrusion, continuous casting, sintering, glass molding, and powder metallurgy due to its ability to withstand extreme conditions while maintaining precision and durability.

Unlike conventional die materials like steel or tungsten carbide, graphite can withstand extreme conditions without deforming or losing performance, making it ideal for applications where precision and repeatability are non-negotiable.

Key Properties of Graphite That Make It Ideal for Industrial Dies

High Thermal Resistance

One of graphite’s most lauded features is its ability to resist thermal shock. Graphite dies maintain structural integrity at temperatures exceeding 3000°C, which is especially beneficial in metal forming and glass molding operations.

Superior Lubricity and Non-Wettability

Graphite’s naturally low friction coefficient reduces tool wear and eliminates the need for additional lubricants. This property also ensures that molten metals or glass do not adhere to the die surface, enhancing surface finish quality and reducing post-processing time.

Excellent Machinability

Graphite can be precisely machined into complex die geometries, offering tighter tolerances and enabling customization. This not only improves part consistency but also lowers production time and cost.

High Electrical Conductivity

This property is essential in electro-discharge machining (EDM) and other electrical processes, where graphite dies act as both the tool and the conductor, allowing for efficient energy use and fine detail.

Industrial Applications Where Graphite Dies Excel

1. Metal Extrusion

Graphite dies are widely used in aluminum, copper, and brass extrusion processes. Their high-temperature endurance and non-reactivity make them ideal for producing rods, bars, tubes, and custom profiles with consistent dimensions and minimal die wear.

2. Continuous Casting of Non-Ferrous Metals

In the continuous casting process, molten metal is poured into graphite molds or dies, solidifying into billets or ingots. Graphite’s thermal conductivity ensures uniform cooling, minimizing defects such as cracks or porosity in the final product.

3. Powder Metallurgy

Graphite dies are integral to the hot pressing and sintering of powdered metals and ceramics. They facilitate uniform pressure distribution, leading to dense, high-strength parts used in aerospace, automotive, and medical device manufacturing.

4. Glass Forming

In the glass industry, graphite dies are used to mold optical components, laboratory glassware, and consumer products. Their high surface quality and heat resistance enable precision forming with minimal surface defects.

5. Diamond Tool Manufacturing

Graphite dies are employed to manufacture polycrystalline diamond (PCD) and cubic boron nitride (CBN) tools. The high-pressure, high-temperature synthesis of these superhard materials necessitates robust, stable dies—a role graphite fulfills effortlessly.

Advantages of Using Graphite Dies Over Traditional Materials

Extended Tool Life

Due to their oxidation resistance and dimensional stability, graphite dies last significantly longer in harsh environments compared to steel or carbide dies. This reduces downtime and replacement costs.

Improved Product Quality

Graphite’s lubricity ensures a smoother die cavity surface, which directly translates to better surface finishes and tighter dimensional tolerances on the final products.

Reduced Maintenance Requirements

With fewer issues related to thermal distortion or corrosion, graphite dies require less frequent maintenance, enhancing overall process efficiency.

Sustainability

Graphite is a recyclable material and generates less waste during machining. Its long service life and reduced need for lubricants contribute to environmentally friendly manufacturing practices.

Types of Graphite Used in Die Manufacturing

Different grades of graphite are used based on the application requirements:

-

Isostatic Graphite: Offers high purity and uniformity; ideal for precision dies in electronics and aerospace.

-

Extruded Graphite: Used in general-purpose dies where extreme precision isn’t as critical.

-

Vibration Molded Graphite: Suitable for large-volume die production due to its cost-efficiency and machinability.

Choosing the correct graphite grade ensures optimal performance, longer die life, and reduced manufacturing defects.

Design Considerations for Graphite Dies

When designing a graphite die, engineers must consider:

-

Thermal load distribution to prevent stress fractures.

-

Part geometry and complexity to determine machinability and die structure.

-

Application-specific requirements, such as corrosion resistance, electrical conductivity, or density.

Proper design not only improves performance but also maximizes ROI on die tooling costs.

Challenges and Mitigation Strategies

Despite their numerous advantages, graphite dies come with challenges:

-

Oxidation at High Temperatures: Use in inert atmospheres or apply protective coatings to enhance lifespan.

-

Brittleness: Handle and machine with care; consider hybrid designs where graphite is supported by tougher materials.

-

Cost: While upfront costs may be higher, long-term savings in durability and performance often outweigh initial expenses.

Conclusion: Why Graphite Dies Are the Future of Industrial Tooling

As modern industries evolve, the demand for materials that offer longevity, efficiency, precision, and environmental benefits continues to rise. Graphite dies not only meet but exceed these demands, making them indispensable in critical industrial sectors.

From high-performance metal forming to glass molding and diamond tool production, the strategic use of graphite dies is revolutionizing the way we think about durability and precision in manufacturing.