Overview of the Benzene Market:

The benzene market is a significant segment of the global chemical industry, primarily focused on the production and distribution of benzene, an aromatic hydrocarbon that is a fundamental building block for various chemicals and materials. Benzene is widely used in the manufacture of plastics, resins, synthetic fibers, rubber, and other important industrial products. Its derivatives, such as ethylbenzene, cumene, and cyclohexane, are crucial in the production of styrene, phenol, and nylon, making benzene an essential component in numerous applications across different industries. The market is influenced by factors such as demand from end-use industries, regulatory policies concerning environmental and health impacts, and fluctuations in raw material prices.

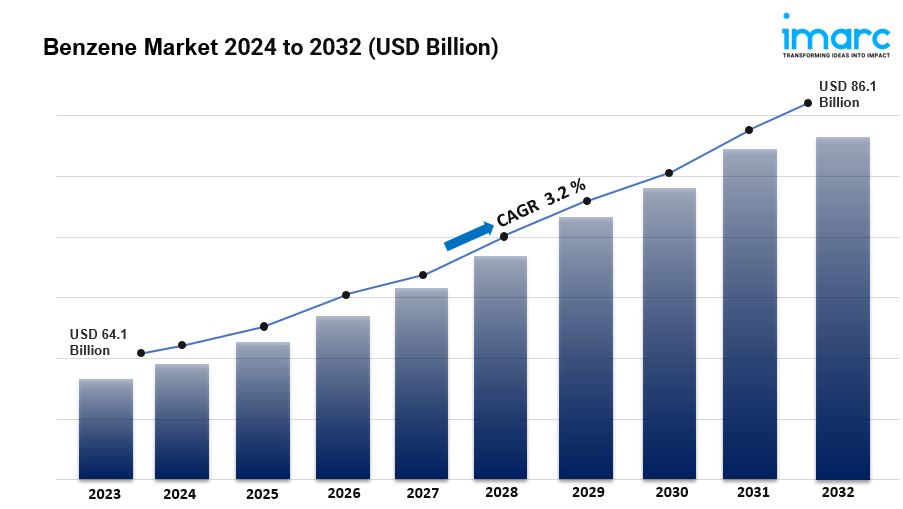

The global benzene market size reached USD 66.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 87.1 Billion by 2033, exhibiting a growth rate (CAGR) of 3.1% during 2025-2033. The implementation of stringent environmental and health regulations, the escalating investment in research and development across the globe, and the increasing demand for increased agricultural production are among the key factors driving the market growth.

Buy Now: https://www.imarcgroup.com/checkout?id=470&method=1670

Key Highlights of the Benzene Market:

Strong Demand from End-Use Industries: The benzene market is primarily driven by robust demand from various end-use industries, including automotive, construction, electronics, and consumer goods. The growth of these sectors, particularly in emerging economies, is leading to increased consumption of benzene and its derivatives. For instance, the automotive industry’s expansion is boosting the demand for synthetic rubber and plastics, which rely on benzene as a key raw material.

Production and Supply Dynamics: Benzene is produced through several processes, including catalytic reforming, steam cracking, and toluene hydrodealkylation. The production capacity of benzene is concentrated in regions with significant petrochemical infrastructure, such as North America, Europe, and Asia-Pacific. Changes in crude oil prices and the availability of feedstocks can significantly impact benzene production and pricing dynamics in the market.

Market Volatility and Pricing Trends: The benzene market is characterized by price volatility influenced by factors such as fluctuations in crude oil prices, supply-demand imbalances, and geopolitical events. Prices of benzene often correlate with those of crude oil and other petrochemical products. This volatility can affect profit margins for manufacturers and impact the overall market dynamics.

Environmental and Regulatory Challenges: Benzene is classified as a hazardous substance due to its toxic properties and potential health risks, including carcinogenic effects. Regulatory bodies in various regions are implementing stringent environmental regulations to limit benzene emissions and exposure. These regulations are prompting manufacturers to adopt cleaner production technologies and improve safety measures, influencing market operations and costs.

Shifts Towards Sustainable Alternatives: There is a growing trend towards sustainability and the adoption of greener alternatives in the chemical industry. As concerns about the environmental impact of benzene and its derivatives increase, companies are exploring bio-based and renewable alternatives. This shift could potentially reshape the benzene market as manufacturers seek to align with sustainability goals and consumer preferences.

Technological Innovations: Advances in technology are playing a crucial role in enhancing benzene production efficiency and reducing environmental impact. Innovations in process optimization, catalyst development, and waste management are enabling manufacturers to improve yields and minimize emissions. The integration of digital technologies, such as automation and data analytics, is also enhancing operational efficiency within the benzene supply chain.

Regional Market Insights: The Asia-Pacific region is the largest market for benzene, driven by rapid industrialization, urbanization, and growing demand from end-use industries. Countries like China and India are significant consumers of benzene, contributing to the region’s dominance in the market. North America and Europe also represent substantial markets, with established petrochemical industries and a focus on innovation and sustainability.

Global Benzene Market Trends:

The benzene market is poised for significant transformation driven by various factors, including regulatory pressures, shifting consumer preferences, and technological innovations. The emphasis on sustainability will continue to shape the industry, as manufacturers seek to comply with stricter environmental regulations while meeting the demands of eco-conscious consumers. This will likely lead to a decline in traditional benzene applications, such as solvents, while fostering growth in alternative uses that align with sustainability goals. Furthermore, the resurgence of key end-user sectors, particularly automotive and construction, will bolster benzene demand, as these industries increasingly rely on benzene derivatives for their products. Technological advancements will further enhance production efficiency, allowing manufacturers to adapt to changing market conditions and reduce costs. Overall, the benzene market in 2025 will reflect a complex interplay of environmental considerations, economic growth, and technological progress, positioning it for both challenges and opportunities in the coming years.

Industry Trends and Drivers:

Regulatory Changes and Environmental Impact:

The benzene market is experiencing significant shifts due to evolving regulatory frameworks aimed at reducing environmental impact and enhancing public health. Governments worldwide are tightening regulations on hazardous substances, including benzene, which is recognized for its carcinogenic properties. In response to these regulations, many industries are investing in cleaner production technologies and alternative materials, leading to a gradual decline in benzene consumption in certain applications. For instance, the automotive and chemical sectors are increasingly adopting greener practices, such as using bio-based feedstocks or developing synthetic alternatives to benzene-derived products. This regulatory pressure is not only reshaping production methods but also influencing market dynamics by creating a competitive landscape where companies that prioritize sustainability may gain a strategic advantage. As a result, the benzene market is likely to see fluctuating demand patterns, with a potential decrease in traditional applications like solvents and an uptick in demand for benzene derivatives that align with environmental standards.

Shifts in Demand from Key End-User Industries:

The demand for benzene is heavily influenced by the performance and growth of key end-user industries, including automotive, construction, and consumer goods. As global economic conditions improve, particularly in emerging markets, there is an increased demand for products that utilize benzene derivatives, such as styrene for plastics and synthetic rubber. The automotive industry, which is undergoing a transformation with the rise of electric vehicles (EVs), is expected to drive demand for lightweight materials, many of which incorporate benzene-based compounds. Moreover, the construction sector is witnessing a rebound, leading to higher consumption of adhesives, coatings, and paints that rely on benzene derivatives. These trends indicate a robust growth trajectory for the benzene market as it adapts to the changing needs of these industries. However, the market must also navigate challenges such as fluctuating raw material prices and supply chain disruptions, which could impact overall demand stability.

Technological Advancements and Production Efficiency:

Technological advancements are playing a crucial role in shaping the benzene market, particularly in enhancing production efficiency and reducing costs. Innovations in catalytic processes and extraction methods are enabling manufacturers to produce benzene more sustainably and economically. For instance, advancements in the use of zeolite catalysts and improved separation techniques are allowing for higher yields and lower energy consumption during benzene production. As companies strive to optimize their operations, these technologies not only improve profitability but also contribute to a reduced environmental footprint. Furthermore, the integration of digital technologies, such as data analytics and automation, is streamlining production processes and enabling better resource management. As these technologies become more widespread, they are expected to drive down production costs and enhance the competitiveness of benzene in the global market. Consequently, the benzene market may witness a shift in supply dynamics, with more efficient producers gaining market share and influencing pricing strategies.

Request for a sample copy of this report: https://www.imarcgroup.com/benzene-technical-material-market-report/requestsample

Benzene Market Report Segmentation:

Breakup By Derivative:

- Ethylbenzene

- Cumene

- Cyclohexane

- Nitrobenzene

- Linear Alkylbenzene

- Maleic Anhydride

- Others

Ethylbenzene account for the majority of shares as it is widely used to produce styrene, which is a precursor for polystyrene.

Breakup By Manufacturing Process:

- Pyrolysis Steam Cracking of Naphtha

- Catalytic Reforming of Naphtha

- Toluene Hydrodealkylation

- Toluene Disproportionation

- From Biomass

Based on the manufacturing process, the market has been divided into pyrolysis steam cracking of naphtha, catalytic reforming of naphtha, toluene hydrodealkylation, toluene disproportionation, and from biomass.

Breakup By Application:

- Plastics

- Resins

- Synthetic Fibers

- Rubber Lubricants

- Others

On the basis of application, the market has been classified into plastics, resins, synthetic fibers, rubber lubricants, and others.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific holds the leading position owing to a large market for benzene driven by its rapid industrialization and the expanding petrochemical industry.

Top Benzene Market Leaders:

The benzene market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies.

Some of the key players in the market are:

- BASF

- Sinopec

- Royal Dutch Shell

- China National Petroleum Corporation

- DuPont

- Saudi Basic Industries Corporation

- China Petroleum & Chemical Corporation

- ExxonMobil Corporation

- JX Holdings

- BP

- Borealis AG

- Braskem

- Repsol

- Arsol Aromatics GmbH & Co. KG

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145