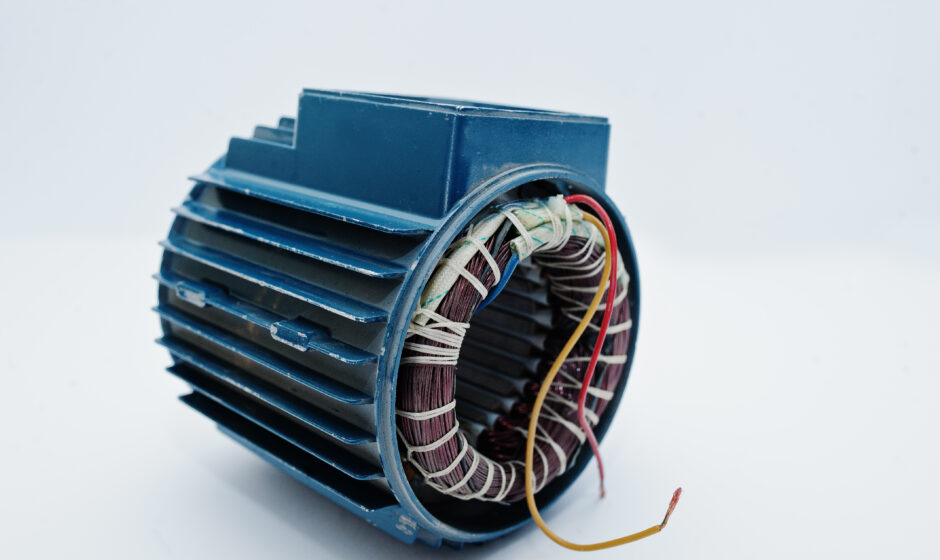

Electric motors power a vast range of devices and equipment in industrial, commercial, and even residential settings. From driving manufacturing machinery to powering HVAC systems and household appliances, electric motors play a crucial role in modern life. However, like all machinery, electric motors can face issues that disrupt their operation and, if left unaddressed, can lead to expensive repairs or replacement. Knowing how to troubleshoot common issues effectively can save time, money, and prevent further damage. This guide explores essential troubleshooting techniques for electric motors, their importance, and benefits, ensuring you can quickly resolve issues and maintain the efficiency of your equipment.

Picking the right industrial company can fundamentally affect your business’ development, functional effectiveness, and productivity.

Importance of Troubleshooting Electric Motors

Electric motors are the backbone of many industries, and downtime due to motor failures can be costly and disruptive. Effective troubleshooting is essential for several reasons:

- Prevention of Downtime: Identifying and resolving issues early helps prevent extended periods of downtime, which is especially crucial in industrial settings where time is money.

- Cost Efficiency: Regular troubleshooting allows for early detection of small issues, which can prevent larger and more expensive repairs.

- Extended Motor Lifespan: Proper maintenance and troubleshooting increase the life of electric motors, enhancing the return on investment for businesses.

- Energy Efficiency: Faulty motors consume more energy, leading to higher operational costs. Troubleshooting keeps the motor running at peak efficiency.

Key Benefits of Troubleshooting Electric Motors

Troubleshooting has several advantages, from improving safety to saving resources. Here are some key benefits:

Enhanced Safety: Electric motor issues, if left unchecked, can lead to overheating or mechanical failure, which may endanger workers. Troubleshooting helps reduce these risks.

Reduction in Maintenance Costs: Routine troubleshooting prevents severe issues, thereby reducing the overall maintenance costs.

Improved Performance: Consistent troubleshooting ensures that electric motors operate efficiently, leading to optimal performance of the equipment they power.

Environmental Impact: Efficiently running motors consume less power and, in turn, produce a smaller carbon footprint, contributing to sustainability goals.

Step-by-Step Troubleshooting Guide for Common Electric Motor Issues

Let’s explore a systematic approach to troubleshooting common problems in electric motors:

1. Understanding the Symptoms of Motor Issues

Before starting with the actual troubleshooting, it’s essential to observe the symptoms of malfunctioning. Common symptoms include:

Unusual noises

Excessive vibration

Overheating

Loss of power or efficiency

Frequent tripping of circuit breakers

Identifying these symptoms can give insights into the possible cause of the problem.

2. Checking Power Supply and Connections

One of the most common issues with electric motors is an inconsistent or inadequate power supply. Start by:

Verifying Voltage and Current: Use a multimeter to check if the motor is receiving the correct voltage and current. Deviations can indicate issues with the power source.

Inspecting Connections: Loose or corroded connections can cause irregular power flow. Ensure all wires and connections are secure and free from rust or corrosion.

Pro Tip: If circuit breakers frequently trip, it could indicate an overloaded motor or a problem with the circuit.

3. Testing Motor Windings

Faulty windings can lead to overheating and reduced efficiency. To check the windings:

Use an Insulation Resistance Tester: This tool helps detect insulation breakdowns. Low insulation resistance indicates a problem with the windings.

Conduct Winding Resistance Tests: Use an ohmmeter to test winding resistance. Discrepancies from the manufacturer’s specifications can suggest damage or shorts within the windings.

4. Assessing Bearing Condition

Bearings are essential components that allow smooth operation of the motor. Problems with bearings can lead to excessive noise, vibration, and heat. To inspect bearings:

Listen for Noise: Run the motor and listen for grinding or rumbling sounds, which can indicate worn bearings.

Check for Vibration: Use a vibration analyzer to identify unusual patterns, which often suggest bearing wear or misalignment.

Inspect for Lubrication: Lack of lubrication is a common cause of bearing failure. Ensure the bearings are adequately greased according to manufacturer recommendations.

Pro Tip: Regularly replace bearings as part of preventive maintenance to avoid unexpected failures.

NOTE: electric motors are gadgets that convert electrical energy into mechanical energy through the collaboration of attractive fields

5. Checking for Overheating Issues

Overheating can severely damage the motor. Common causes of overheating include poor ventilation, excessive load, and electrical issues. To troubleshoot:

Monitor Ambient Temperature: Ensure the environment around the motor allows for sufficient cooling. Dust and obstructions can block airflow and cause overheating.

Measure Motor Temperature: Use a thermal imaging camera or temperature probe to measure the motor’s temperature. Excessive heat may indicate an overload or insulation problem.

Pro Tip: Install thermal overload protection systems to automatically shut down the motor when it reaches unsafe temperature levels.

Tips for Preventive Maintenance of Electric Motors

Preventive maintenance is crucial to minimize the need for extensive troubleshooting and ensures a long motor life. Here are a few tips for effective maintenance:

- Regular Inspections: Inspect your motor’s condition every month for signs of wear, unusual noise, or heat.

- Routine Lubrication: Maintain an optimal level of lubrication in bearings to prevent excessive friction and wear.

- Maintain a Clean Environment: Dust and debris can impede cooling and cause overheating, so keep the motor and its surroundings clean.

- Check Voltage Levels Regularly: Ensure your motor receives the recommended voltage to avoid performance issues.

Final Thoughts

Troubleshooting electric motors requires a systematic approach and an understanding of common motor problems. From power supply issues to mechanical faults in bearings and rotors, identifying the problem early can save significant time and expense. Regular troubleshooting and preventive maintenance are essential for ensuring optimal motor performance, reducing downtime, and extending the life of your equipment.

With proper troubleshooting knowledge, you can avoid costly repairs, reduce energy consumption, and maintain safety in your operations. Whether you’re a maintenance engineer or a facility manager, understanding these troubleshooting techniques equips you to handle issues efficiently and keep your systems running smoothly.