Industrial filtration is a critical process across various industries, ensuring the separation of solids from liquids to maintain product quality and meet regulatory standards. Among the numerous filtration systems available today, the zero hold up filter press has emerged as a revolutionary solution due to its efficiency and minimal product loss. Leading zero hold up filter press manufacturers are at the forefront of this innovation, driving advancements in technology to cater to the ever-evolving needs of industries such as pharmaceuticals, chemicals, food and beverages, and more.

In this article, we delve into the latest innovations introduced by top manufacturers and explore how they are redefining industrial filtration standards.

What Is a Zero Hold Up Filter Press?

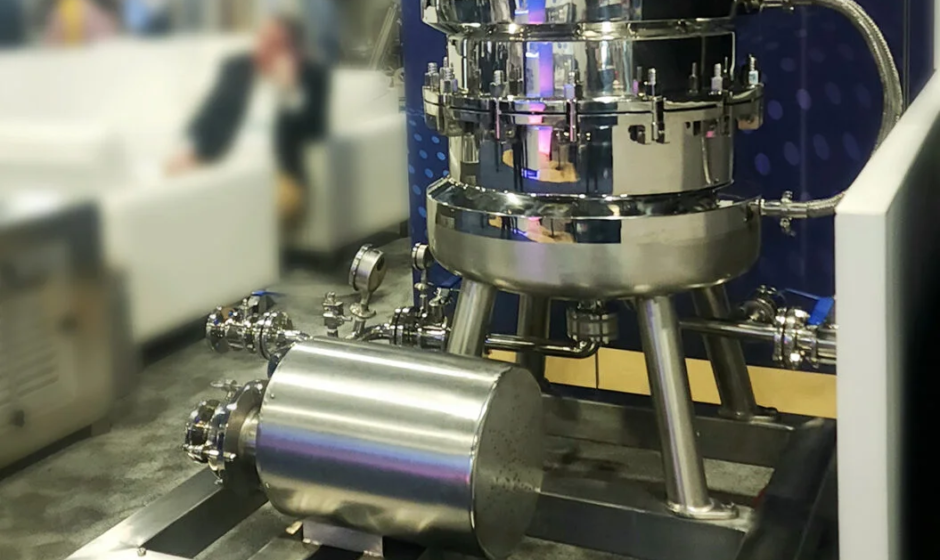

A zero hold up filter press is a specialized piece of equipment designed to minimize the retention of unfiltered liquid during the filtration process. Unlike traditional filter presses that may retain some product in the system, these advanced filters ensure that all the material is pushed through the filter, leaving virtually no residue behind. This results in higher product yield, reduced waste, and enhanced operational efficiency.

These systems are widely used in industries requiring high purity and precision, making them indispensable for modern manufacturing processes.

Role of Leading Manufacturers in Advancing Filtration Technology

Leading zero hold up filter press manufacturers have been instrumental in elevating the standards of industrial filtration. Their continuous research and development efforts have resulted in the introduction of cutting-edge features and technologies, making these systems more efficient, reliable, and user-friendly.

Here are some of the notable innovations by these manufacturers:

1. Advanced Filtration Media

Modern zero hold up filter presses now use highly specialized filtration media, including multi-layered and chemically resistant materials. This ensures compatibility with a wide range of liquids, including corrosive chemicals, viscous solutions, and delicate pharmaceutical products.

2. Improved Hydraulic Mechanisms

Hydraulic systems play a vital role in the operation of a filter press. Manufacturers have introduced advanced hydraulic mechanisms for automated plate shifting and uniform pressure distribution. This innovation not only improves filtration efficiency but also reduces manual intervention and operational downtime.

3. Compact and Modular Designs

Space constraints are a significant challenge for many industries. Leading manufacturers now offer compact and modular designs for zero hold up filter presses, allowing seamless integration into existing production lines. These designs also facilitate easier maintenance and scalability.

4. Enhanced Clean-in-Place (CIP) Systems

A critical requirement in industries like pharmaceuticals and food processing is maintaining high hygiene standards. Innovations in CIP systems by zero hold up filter press manufacturers in India have made it easier to clean and sanitize the equipment between batches, ensuring compliance with stringent quality standards.

5. Energy-Efficient Solutions

Sustainability is a key focus for manufacturers today. Energy-efficient motors and optimized filtration cycles have been introduced to reduce energy consumption while maintaining superior performance. These solutions align with the growing demand for eco-friendly industrial practices.

Applications of Zero Hold Up Filter Presses

The versatility of zero hold up filter presses has made them a preferred choice across diverse industries. Here are some of their key applications:

1. Pharmaceutical Industry

In the pharmaceutical sector, precision is paramount. Zero hold up filter presses ensure the efficient filtration of active pharmaceutical ingredients (APIs), syrups, and other formulations without contamination or product loss.

2. Chemical Industry

Chemical manufacturers rely on these systems to filter corrosive liquids and viscous solutions. The robust construction and compatibility with various chemicals make zero hold up filter presses indispensable in this sector.

3. Food and Beverage Industry

From filtering edible oils to clarifying beverages, these presses help maintain product quality and meet food safety standards. Their ability to handle high volumes efficiently is a significant advantage for large-scale production.

4. Cosmetics Industry

Cosmetic formulations often require fine filtration to remove impurities. Leading manufacturers have developed specialized filters tailored to the unique requirements of this industry.

Why Indian Manufacturers Are Leading the Way

India has emerged as a global hub for industrial filtration equipment, thanks to its robust manufacturing capabilities and focus on innovation. Top zero hold up filter press manufacturers in India are renowned for producing high-quality systems at competitive prices.

Factors Contributing to Their Success

- State-of-the-Art Facilities: Indian manufacturers invest in modern production facilities equipped with advanced machinery and quality control systems.

- Customizable Solutions: They offer tailor-made systems to meet the unique requirements of different industries.

- Strong R&D Focus: Continuous innovation and research enable Indian manufacturers to stay ahead of global competition.

- Cost-Effectiveness: Indian manufacturers provide world-class equipment at affordable prices, making them a preferred choice worldwide.

Choosing the Right Zero Hold Up Filter Press Manufacturer

Selecting the right zero hold up filter press manufacturer is crucial for ensuring the efficiency and reliability of your filtration processes. Here are some key factors to consider:

1. Experience and Expertise

Choose a manufacturer with a proven track record and extensive experience in designing and manufacturing filtration equipment.

2. Quality Standards

Ensure that the equipment complies with international quality standards, such as ISO and GMP certifications, especially if you operate in regulated industries like pharmaceuticals or food processing.

3. After-Sales Support

Reliable after-sales support, including maintenance services and spare parts availability, is essential for long-term performance.

4. Customization Options

Look for manufacturers who offer customizable solutions to address your specific needs.

5. Reputation in the Market

Research customer reviews and testimonials to gauge the reputation of the manufacturer.

The Future of Zero Hold Up Filter Press Technology

The future of industrial filtration lies in automation and sustainability. Leading zero hold up filter press manufacturers are already exploring technologies like IoT-enabled monitoring, predictive maintenance, and AI-driven optimization to enhance the efficiency and reliability of their systems.

Additionally, the focus on sustainable practices is driving the development of energy-efficient designs and recyclable filtration media, further reducing the environmental impact of industrial operations.

Conclusion

The innovations introduced by top zero hold up filter press manufacturers are transforming the landscape of industrial filtration technology. With advancements in design, automation, and sustainability, these systems are helping industries achieve higher productivity, better product quality, and lower operational costs.

India, in particular, has established itself as a leader in this domain, thanks to its expertise, cost-effective solutions, and commitment to innovation. Whether you’re in the pharmaceutical, chemical, or food processing industry, investing in a high-quality zero hold up filter press from a trusted manufacturer is a step toward optimizing your production processes.