The application of ionic liquids in green chemistry has expanded as environmental consciousness has grown. Because they are made entirely of ions, these salts stay liquid at comparatively low temperatures. In contrast to conventional organic solvents, they have significant solvation capabilities, great thermal stability, and minimal vapor pressure. These qualities improve the safety and effectiveness of industrial operations, lessen environmental risks, and promote sustainable chemical processes. Their importance in reducing the use of dangerous solvents and improving production techniques is further enhanced by their capacity to customize molecular architectures. Ionic liquids’ wide range of applications and environmentally beneficial qualities are driving up demand for them in a variety of industries, highlighting their significance in industrial green chemistry.

Unique Structural Features

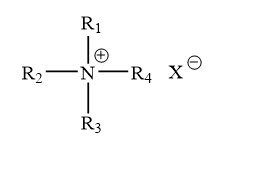

Large, asymmetric organic cations combined with diverse anions prevent the formation of rigid crystalline lattices, allowing these substances to stay liquid under ambient conditions. Variations in cation and anion combinations enable the development of task-specific fluids with controlled viscosity, polarity, conductivity, and hydrophobicity. For access to a wide range of Ionic Liquids with customized properties, high-purity options are available for research and industrial use. This design flexibility meets the complex demands of modern chemical processes while maintaining a focus on sustainability. The customization potential of Ionic Liquids continues to drive innovations in catalysis, energy storage, and environmental cleanup.

Advances in Catalysis

Ionic liquids play a transformative role in catalysis, offering numerous advantages over traditional solvents. By providing stable and controlled reaction environments, they significantly enhance the performance of catalysts. This is particularly crucial in chemical processes where traditional solvents may present safety hazards, such as flammability or toxicity. Ionic liquids exhibit high thermal stability and excellent solvation abilities, which aid in improving both the efficiency and selectivity of reactions.

In the realm of catalytic systems, ionic liquids have shown tremendous success in facilitating complex chemical reactions such as cross-coupling, hydroformylation, and hydrogenation. These reactions are integral in the synthesis of high-value chemicals and materials. The use of ionic liquids in these processes leads to higher product yields and more straightforward separation processes, reducing the need for excessive purification steps.

Moreover, because catalysts can remain dissolved in the ionic liquid phase, they can often be recovered and reused multiple times with minimal loss of activity. This reuse not only cuts costs but also aligns with sustainable practices by reducing waste and the need for fresh catalyst materials. These catalytic advantages are particularly valuable in the production of fine chemicals, pharmaceuticals, and agrochemicals. These industries demand high precision and production efficiency, and the unique properties of ionic liquids make them ideal candidates for enhancing these characteristics.

Carbon Dioxide Capture

The issue of carbon emissions is a significant environmental challenge, and ionic liquids offer a promising solution for carbon dioxide capture. By carefully adjusting the molecular structure of ionic liquids, researchers have developed systems that selectively absorb carbon dioxide. This selectivity arises from the strong interactions between CO₂ molecules and the ionic framework of the liquids, which enhances the capacity for CO₂ capture while lowering the energy required for regeneration.

These properties make ionic liquids highly effective for use in industrial facilities where carbon capture is essential. Typically applied to treat post-combustion gas streams, ionic liquids outperform traditional amine-based solvents by providing improved performance and minimizing problems related to volatility and degradation. Unlike many conventional options, ionic liquids have low vapor pressure, which reduces the risk of evaporation and associated loss during processing.

Beyond power plants, other sectors such as cement production and steel manufacturing are increasingly adopting ionic liquids for their carbon capture needs. This shift showcases the broader potential of ionic liquids in environmental protection. Their versatility in capturing CO₂ from various industrial processes highlights their growing appeal as industries strive to reduce their carbon footprints and comply with stringent environmental regulations. By integrating ionic liquids into these processes, industries can achieve more sustainable operations and contribute to global efforts in reducing greenhouse gas emissions.

Biomass Processing

The pretreatment of lignocellulosic biomass benefits from the dissolving power of ionic liquids, making the breakdown of cellulose and lignin more efficient. Milder operating conditions replace harsh chemical methods, increasing material recovery and supporting the production of renewable products such as biofuels and bioplastics. Processing steps become less energy-intensive, contributing to more sustainable resource utilization. This application aligns with the growing global trend toward bio-based alternatives to petroleum-derived products, further highlighting the role of ionic liquids in driving the green chemistry revolution.

Performance in Electrochemical Devices

Energy storage technologies incorporate ionic liquids as advanced electrolytes. High ionic conductivity, wide electrochemical windows, and non-flammable properties ensure reliable performance in batteries, supercapacitors, and solar cells. Devices achieve longer operational lifespans, improved efficiency, and higher safety standards compared to systems using conventional electrolytes. As the demand for sustainable and safe energy storage solutions continues to grow, ionic liquids are expected to play a critical role in the development of next-generation electrochemical devices, reducing reliance on hazardous materials and enhancing overall system performance.

The extensive range of uses for ionic liquids in various industries demonstrates their increasing significance in green chemistry. They are positioned as a crucial option for the sustainable future of industrial operations due to their adaptability and environmental advantages.

View Other Science Blogs.